Brilliant Strategies Of Info About What Is Hmi In SCADA

SCADA Solution Binary Profes Professional Service And

Unlocking the Secrets of HMI in SCADA

1. What Exactly is HMI? Let's Break it Down

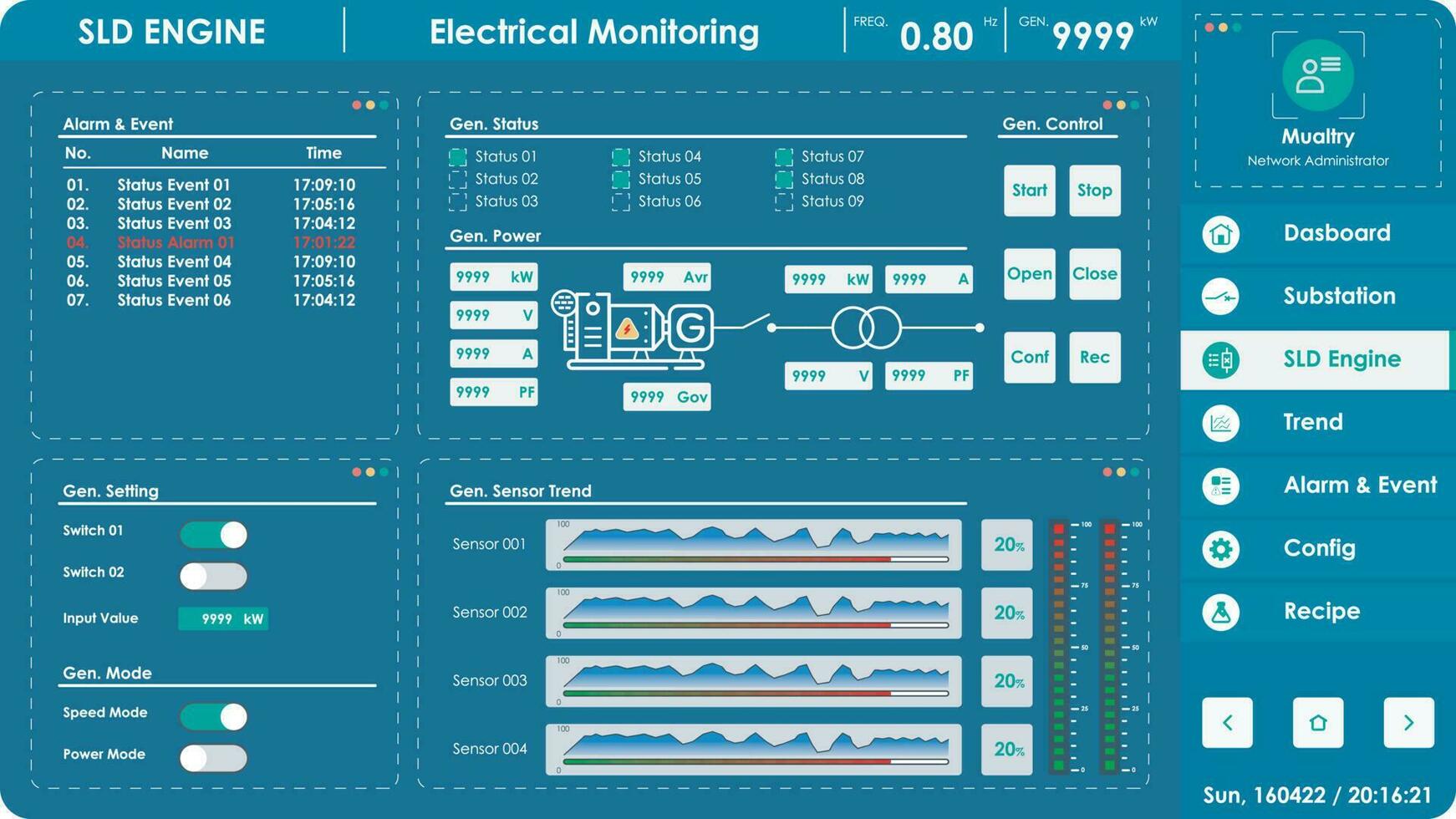

Ever wondered how operators in those fancy control rooms manage complex systems? The secret sauce often involves something called an HMI, or Human-Machine Interface. It's essentially the bridge between us humans and the intricate world of machines and processes controlled by a SCADA system. Think of it as the dashboard of a very, very important machine. It takes all that complicated data and presents it in a way that makes sense to us mere mortals.

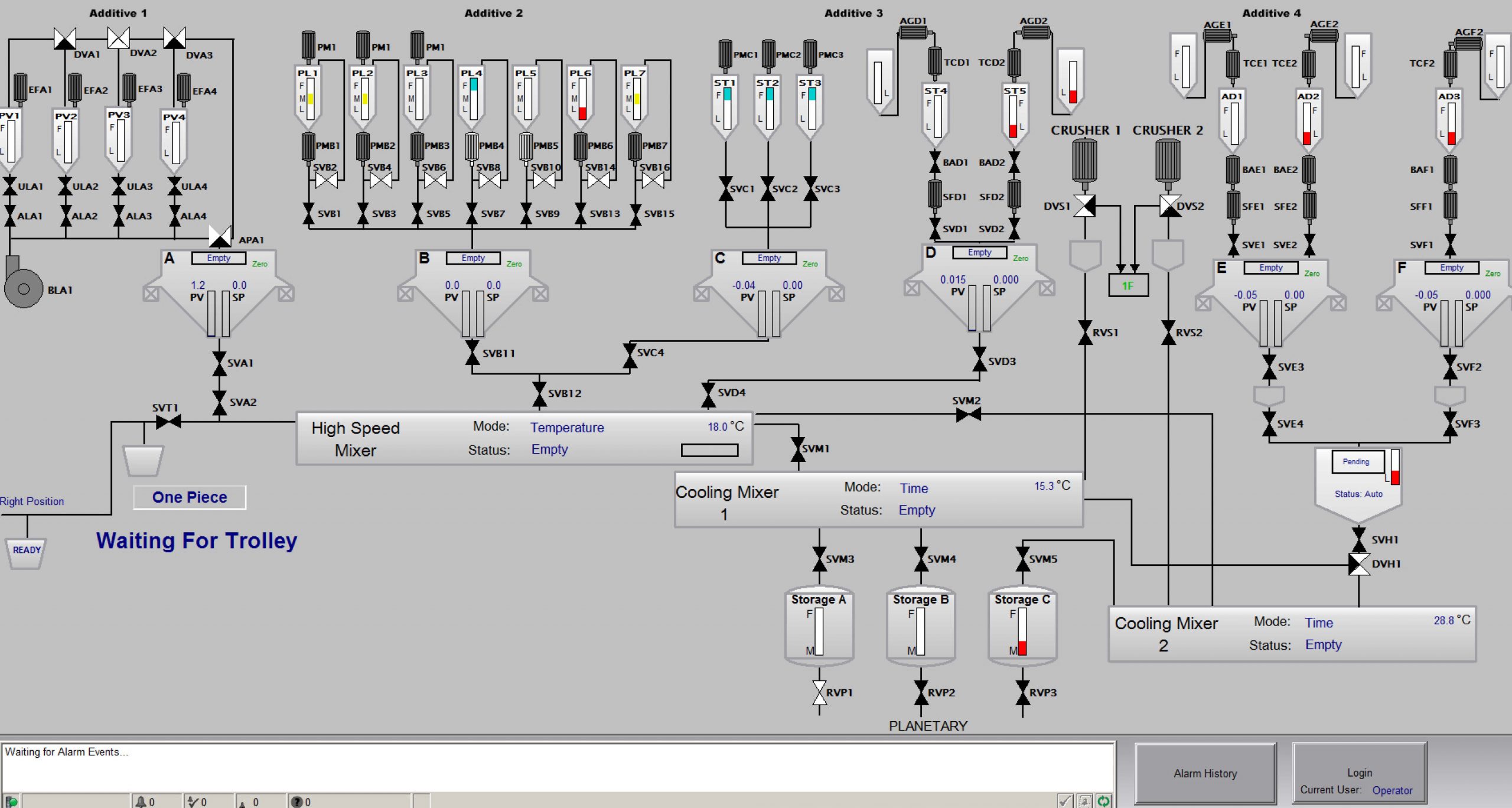

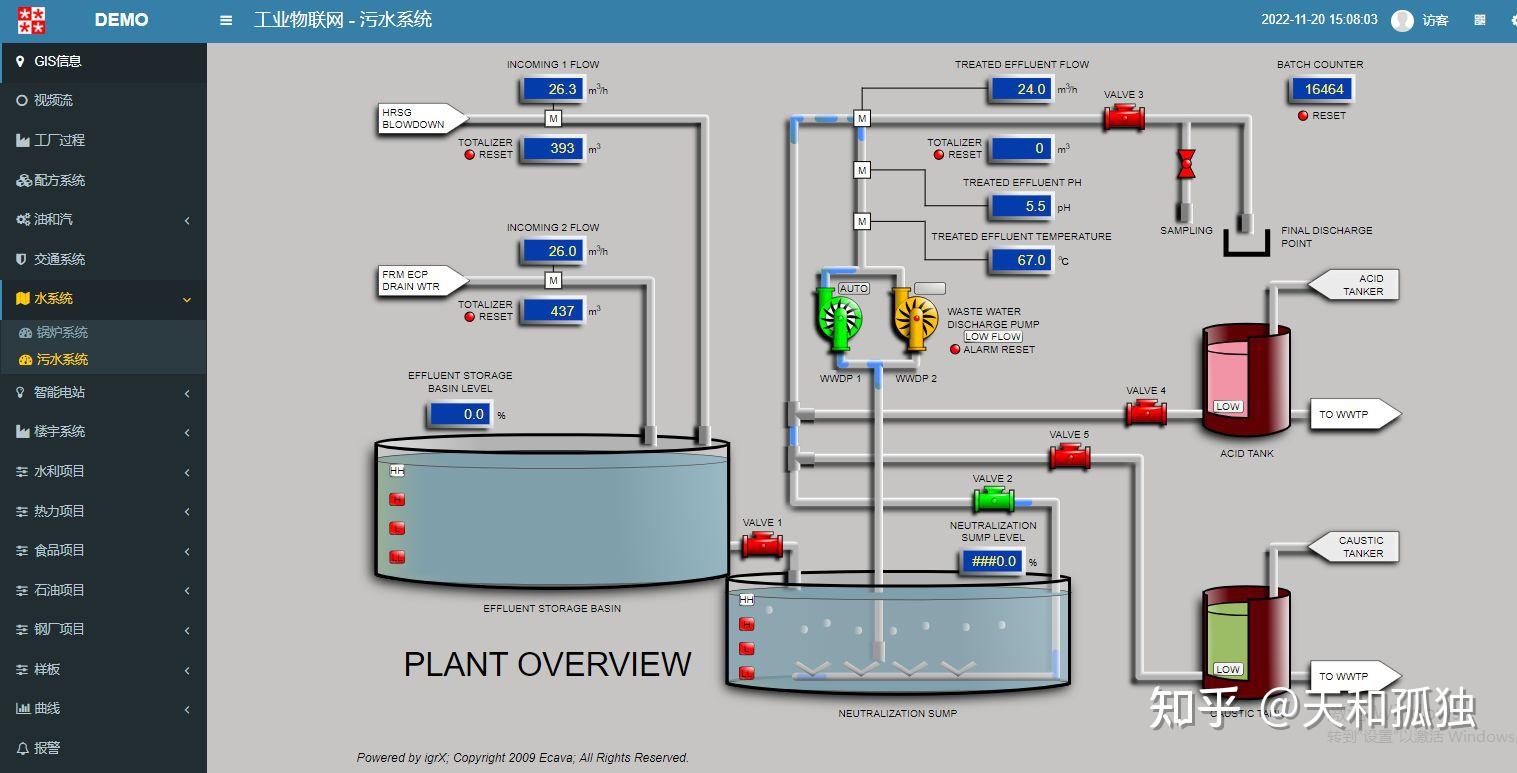

Imagine trying to understand the inner workings of a water treatment plant by staring at raw code. Not exactly a walk in the park, right? That's where the HMI steps in. It translates those cryptic numbers and signals into visual representations like graphs, charts, and even animated diagrams, providing a clear and intuitive view of what's happening in real-time. This allows operators to monitor, control, and troubleshoot issues quickly and efficiently, preventing potential disasters.

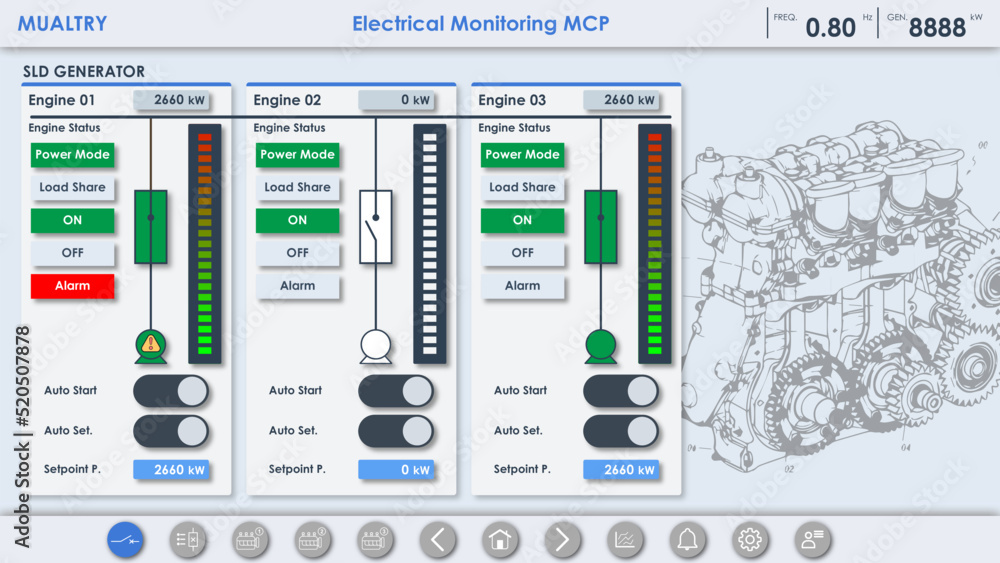

But it's more than just pretty pictures. The HMI also allows operators to send commands to the SCADA system. They can adjust settings, start and stop processes, and respond to alarms, all through a user-friendly interface. Its like having a remote control for your entire industrial operation. Without an HMI, managing a complex SCADA system would be like trying to navigate a maze blindfolded — chaotic and prone to errors!

So, in a nutshell, the HMI is the window into your SCADA system. It's the tool that makes sense of the complex data and gives operators the power to manage and control their processes effectively. Its the reason why they dont need to speak fluent binary to keep things running smoothly. And that, my friend, is a very good thing.

HMI SCADA UI Template Industrial Flat Design Stock Vector Adobe

Why is HMI So Crucial in SCADA Systems?

2. The Indispensable Role of HMI in SCADA

Okay, we know what an HMI is, but why is it so darn important in a SCADA (Supervisory Control and Data Acquisition) system? The answer lies in the sheer complexity of the processes SCADA systems manage. We're talking about pipelines stretching for miles, power grids serving entire cities, and manufacturing plants churning out products at lightning speed. Without a clear and accessible way to monitor and control these operations, things could quickly go south.

Think about a power grid. Imagine trying to manage the flow of electricity across an entire region without real-time data on voltage, current, and transformer loads. It would be like driving a car with your eyes closed — reckless and incredibly dangerous. The HMI provides operators with that crucial real-time information, allowing them to anticipate problems, prevent outages, and ensure a stable power supply. It's the difference between a city humming with electricity and a city plunged into darkness.

Beyond preventing disasters, HMIs also improve efficiency and productivity. By providing clear visualizations of key performance indicators (KPIs), they allow operators to identify bottlenecks, optimize processes, and make data-driven decisions. For example, in a manufacturing plant, an HMI can track production rates, identify equipment malfunctions, and even predict maintenance needs. This allows managers to fine-tune their operations and maximize output, saving time and money.

Furthermore, HMIs play a vital role in safety and security. By alerting operators to abnormal conditions and potential hazards, they enable quick and effective responses to emergencies. They can also be used to implement security protocols, such as access controls and intrusion detection systems, protecting critical infrastructure from unauthorized access and cyber threats. In today's interconnected world, this level of security is more important than ever.

Key Features and Functionality of an HMI

3. Diving Deeper

So, we've established that HMIs are important, but let's get down to the specifics. What can an HMI actually do? The answer is: a whole lot! Think of it as a Swiss Army knife for industrial control systems. It's packed with features designed to make operators' lives easier and improve the overall performance of the SCADA system.

One of the most important features is real-time data visualization. HMIs can display data in a variety of formats, including graphs, charts, gauges, and animated simulations. This allows operators to quickly grasp the current state of the system and identify any potential problems. Some HMIs even incorporate augmented reality (AR) elements, overlaying real-time data onto live video feeds for enhanced situational awareness.

Another key functionality is alarm management. HMIs are designed to alert operators to abnormal conditions and potential hazards. They can trigger alarms based on pre-defined thresholds, notify operators via audible alerts and visual cues, and even automatically initiate corrective actions. The best HMIs provide clear and concise alarm summaries, allowing operators to quickly prioritize and respond to the most critical issues. Imagine a control room without alarms — a recipe for disaster!

Beyond visualization and alarms, HMIs also provide powerful control capabilities. Operators can use the HMI to start and stop processes, adjust setpoints, and even manually override automatic controls. They can also use the HMI to access historical data, analyze trends, and generate reports. This allows them to identify patterns, optimize performance, and make informed decisions about future operations. It's like having a crystal ball for your industrial process.

Different Types of HMIs

4. Exploring the HMI Landscape

Not all HMIs are created equal. Just like cars, they come in a variety of shapes, sizes, and functionalities. The type of HMI you need depends on the specific requirements of your SCADA system, your budget, and the skills of your operators. From simple, standalone displays to sophisticated, distributed systems, there's an HMI out there for every application.

At the simpler end of the spectrum, you have panel-mounted HMIs. These are typically small, ruggedized devices designed to be installed directly on equipment or control panels. They often feature touchscreens and offer a limited set of functionalities, such as data display, alarm annunciation, and basic control. They're ideal for smaller applications where simplicity and cost-effectiveness are paramount.

Moving up the scale, you have PC-based HMIs. These are software applications that run on standard computers and offer a wider range of features and functionalities. They can display more complex graphics, integrate with other systems, and support more advanced control algorithms. PC-based HMIs are often used in larger control rooms where operators need access to a comprehensive view of the SCADA system. They're like the SUVs of the HMI world — versatile and capable.

At the top of the food chain, you have distributed HMIs. These are sophisticated systems that consist of multiple HMIs networked together, providing a unified view of the SCADA system across multiple locations. They often incorporate advanced features such as redundancy, remote access, and cybersecurity protections. Distributed HMIs are typically used in large, geographically dispersed organizations where reliability and security are critical. They're the limousines of the HMI world — luxurious, powerful, and designed for the most demanding applications.

HMI SCADA UI Template Industrial Flat Design Stock Vector Adobe

The Future of HMI in SCADA

5. Looking Ahead

The world of HMI is constantly evolving. As technology advances and industries become more complex, HMIs are adapting to meet the changing needs of operators and SCADA systems. So, what does the future hold for HMI? Let's take a peek into our crystal ball and explore some of the emerging trends and innovations.

One of the biggest trends is the increasing use of mobile technology. Operators are demanding the ability to access and control their SCADA systems from anywhere, using smartphones and tablets. This requires HMIs to be accessible via web browsers and to support mobile-friendly interfaces. Mobile HMIs allow operators to respond to alarms and make adjustments on the go, improving their efficiency and responsiveness. It's like having your control room in your pocket!

Another important trend is the integration of artificial intelligence (AI) and machine learning (ML). AI-powered HMIs can analyze vast amounts of data, identify patterns, and predict potential problems before they occur. They can also automate routine tasks, freeing up operators to focus on more critical issues. ML algorithms can even learn from operator behavior and optimize the HMI interface to improve usability and efficiency. Its like having a super-intelligent assistant in your control room.

Finally, cybersecurity is becoming an increasingly important consideration in HMI design. As SCADA systems become more interconnected, they become more vulnerable to cyberattacks. Modern HMIs are incorporating advanced security features such as encryption, authentication, and intrusion detection systems to protect against these threats. They're also being designed to be more resilient to attacks, ensuring that critical systems remain operational even in the event of a breach. It's like building a fortress around your control room.