Peerless Tips About Can I Use Arduino Instead Of PLC

Arduino Versus PLC

1. Understanding the Key Differences

So, you're thinking about automating something, huh? Maybe a small manufacturing process, a home automation system, or even a sophisticated robot that makes you coffee (a worthy goal, in my opinion). You've probably stumbled upon both Arduino and Programmable Logic Controllers (PLCs) and are now wondering, "Can I use Arduino instead of a PLC?" It's a valid question! Both are microcontrollers, but they operate in different universes, really. Think of it like comparing a nimble sports car to a reliable work truck — both get you places, but theyre designed for very different jobs.

PLCs are industrial-grade workhorses. Theyre built to withstand harsh environments like extreme temperatures, vibrations, and electrical noise. Imagine them happily chugging away in a factory surrounded by sparks and loud machinery. Arduino, on the other hand, is more like a sensitive artist. It's great for prototyping and hobby projects, but it might not hold up too well if you dunk it in oil or leave it out in a blizzard. Okay, maybe thats a bit dramatic, but you get the picture.

A key distinction lies in their programming. PLCs often use ladder logic, a visual programming language that mimics electrical schematics. Its designed to be easily understood by electricians and technicians already familiar with relay-based control systems. Arduino typically uses C or C++, which is more versatile but might require a steeper learning curve if you're not a software developer. Think of it as the difference between drawing a simple circuit diagram and writing a complex computer program.

Finally, consider the scale and complexity of your project. For small, isolated tasks, Arduino might be perfectly fine. But for larger, more complex systems involving multiple inputs, outputs, and safety considerations, a PLC is usually the better choice. It's like deciding whether to use a bicycle or a bus — both are modes of transportation, but one is better suited for carrying a larger number of passengers.

Safety First

2. The Critical Role of Reliability

Let's talk about safety. In an industrial environment, a malfunctioning control system can have serious consequences. A runaway machine, a chemical spill — these are not things you want to mess around with. PLCs are designed with safety in mind. They undergo rigorous testing and certification to ensure they operate reliably and predictably, even in worst-case scenarios. They often have built-in redundancy and fail-safe mechanisms that can shut down the system in case of a problem.

Arduino, while capable, doesn't have the same level of built-in safety features or certifications. It's up to the user to implement safety measures, which can be a complex and time-consuming task. It's like building your own safety net — you can do it, but you need to know what you're doing, and you need to be absolutely sure it will work when you need it most.

This isn't to say that Arduino can't be used in industrial applications at all. However, it typically requires additional safety components and a thorough risk assessment to ensure it meets the required safety standards. And frankly, at that point, you might be better off just using a PLC in the first place. Sometimes, the right tool for the job is the one specifically designed for it.

Think of it this way: Would you trust a homemade parachute when skydiving? Probably not. You'd want something that has been tested and certified to meet certain safety standards. The same principle applies to control systems in industrial environments. Safety is paramount, and PLCs are generally the safer option.

The Cost Factor

3. Balancing Affordability and Capability

Okay, let's address the elephant in the room: cost. Arduino boards are significantly cheaper than PLCs. You can pick up an Arduino Uno for a few dollars, while a decent PLC can easily cost hundreds or even thousands. This price difference makes Arduino very attractive for hobbyists, students, and small businesses with limited budgets. It allows for experimentation and rapid prototyping without breaking the bank.

However, it's important to consider the total cost of ownership. While the initial cost of an Arduino might be lower, you might end up spending more in the long run on additional components, enclosures, and development time. Remember that whole safety net analogy? Same applies here. You might save money initially, but if you have to build a lot around it, is it still the best deal?

PLCs, on the other hand, often come with a suite of software tools and support resources that can simplify development and maintenance. They are also designed for long-term reliability, which can reduce downtime and repair costs. It's like buying a more expensive car — the initial investment is higher, but it might last longer and require less maintenance than a cheaper car. Sometimes you do get what you pay for.

Ultimately, the best choice depends on your specific needs and budget. If you're building a small, non-critical project on a shoestring budget, Arduino might be a good option. But if you need a robust, reliable, and safe control system for an industrial application, a PLC is usually the better investment. It's about balancing affordability with capability and long-term cost-effectiveness.

Arduino PLC IDE Tutorial 2 Analog I/O And External Devices Technical

DIY Dreams vs. Industrial Realities

4. Choosing the Right Tool for the Task

So, back to the original question: Can I use Arduino instead of a PLC? The answer, as with most engineering questions, is "it depends." For simple home automation projects, like controlling your lights or watering your plants, Arduino is often a great choice. It's easy to use, affordable, and there's a huge online community for support.

However, for larger, more complex industrial applications, PLCs are generally the preferred solution. They are more reliable, more robust, and designed with safety in mind. They also offer better support for industrial communication protocols and integration with other equipment. Its really about the right tool for the job, isnt it? You wouldn't use a hammer to screw in a screw (well, you could, but it wouldn't be pretty).

Consider your risk tolerance. If a failure of your control system could result in significant financial loss, property damage, or even injury, then a PLC is almost certainly the better choice. It's like choosing between a cheap lock and a high-security lock for your front door — the cheap lock might be fine for a shed, but you wouldn't trust it to protect your home.

In summary, Arduino is great for DIY projects and prototyping, while PLCs are the workhorses of the industrial world. Understanding their strengths and weaknesses will help you make the right decision for your specific application. And remember, always prioritize safety!

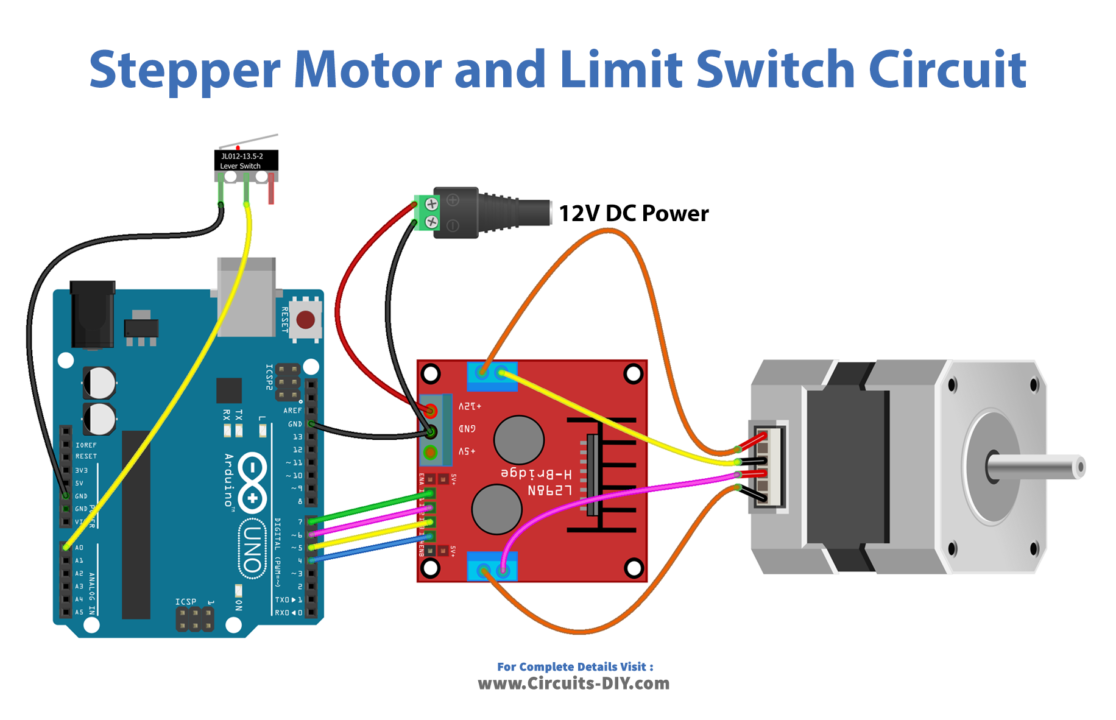

How To Wire A Limit Switch An Arduino

Frequently Asked Questions (FAQs)

5. Addressing Common Queries

Let's tackle some common questions about Arduino vs. PLC.

6. Can I use Arduino in a commercial product?

Yes, you can! Many small businesses use Arduinos in their products. However, you need to consider the reliability, safety, and regulatory requirements of your specific application. You might need to add additional components and certifications to ensure your product meets the necessary standards.

7. Is it possible to make Arduino as reliable as PLC by adding extra components?

While you can improve the reliability of an Arduino with extra components like surge protectors, robust enclosures, and redundant power supplies, it's difficult to achieve the same level of reliability as a PLC. PLCs are designed from the ground up for industrial environments and undergo rigorous testing to ensure their reliability. It's like trying to turn a bicycle into a motorcycle — you can add an engine, but it's still not going to perform like a purpose-built motorcycle.

8. What are the alternatives to ladder logic for PLC programming?

While ladder logic is the most common programming language for PLCs, there are alternatives, such as structured text, function block diagrams, sequential function charts, and instruction list. These languages offer more flexibility and power for complex applications. Think of it as having different tools in your toolbox — some tools are better suited for certain tasks than others.