The Secret Of Info About Where Is Torque Sensor

Unlocking the Mystery

1. Digging Deeper

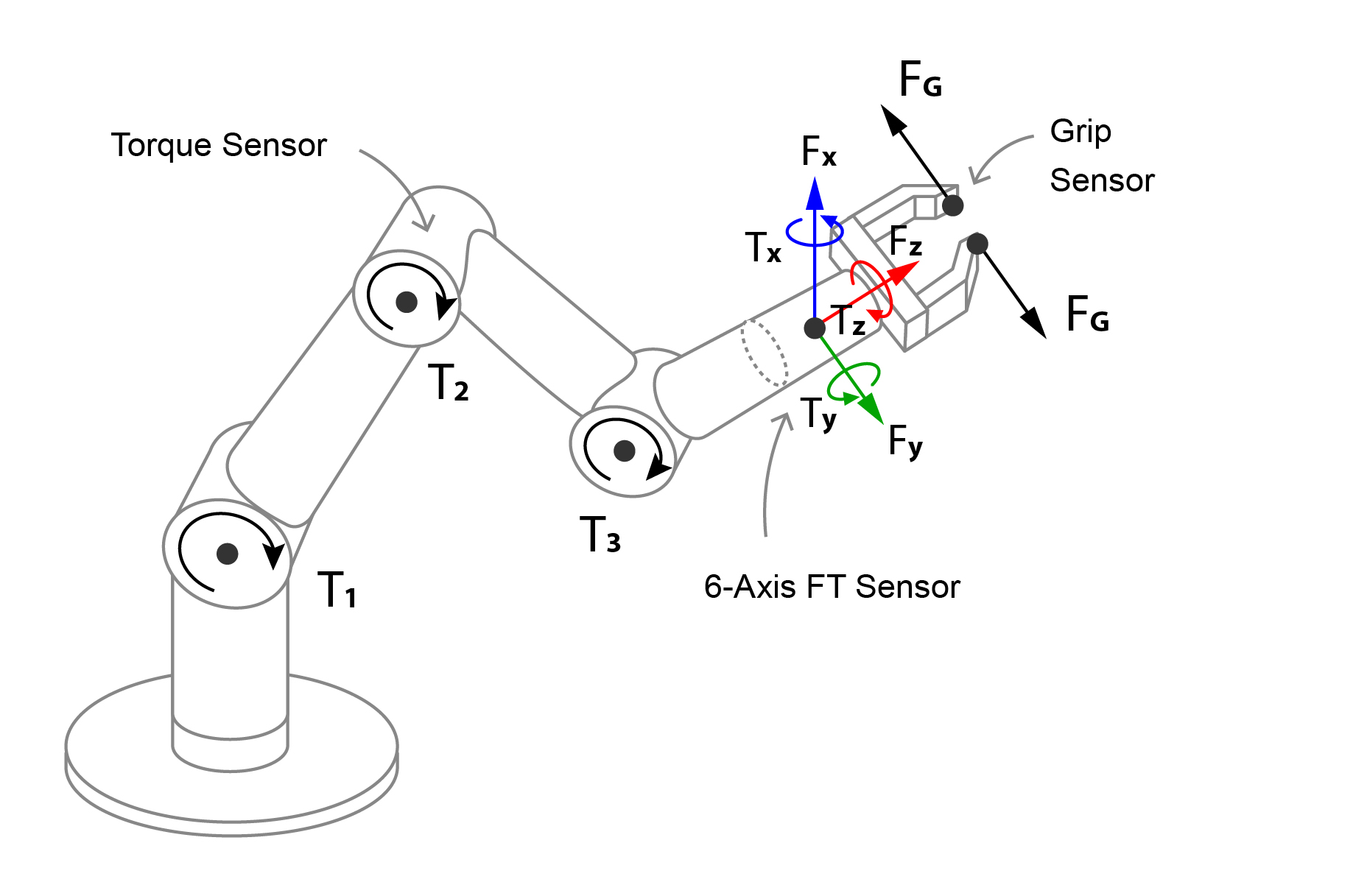

Ever wondered where that sneaky little torque sensor is hiding in your car, e-bike, or power tool? Its a crucial component, constantly working behind the scenes to measure rotational force. But pinpointing its exact location can sometimes feel like a game of hide-and-seek. Don't worry, though; we're here to give you some hints, not breadcrumbs, to follow.

Generally, the placement of a torque sensor depends heavily on its application. In vehicles with electric power steering (EPS), you'll often find it nestled within the steering column, right where it can detect the force you're applying to the wheel. Think of it as the car's way of understanding how hard you're trying to turn, so it can give you the perfect amount of power assist. Its like the car saying, "I got you, fam!"

Now, if we shift gears (pun intended!) and talk about e-bikes, things get a bit different. On an e-bike, a torque sensor might be located in the bottom bracket — that area where the pedals attach to the frame. This placement allows it to accurately gauge how much effort you're putting into pedaling. The sensor then tells the motor how much assistance to provide. So, the harder you pedal, the more the motor kicks in, making those uphill climbs a breeze. It is the magic of seamless riding experience.

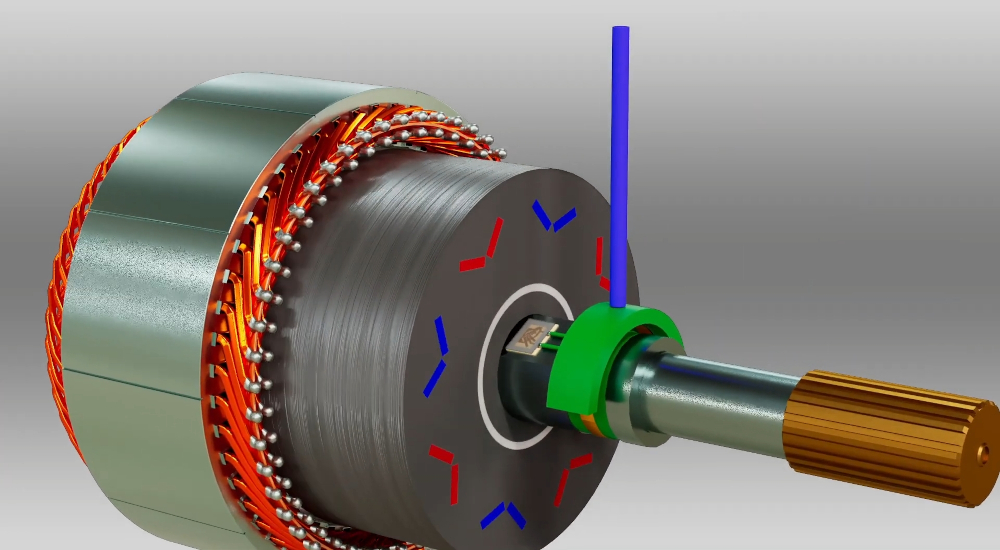

And what about power tools? In tools like electric screwdrivers or wrenches, the torque sensor is usually integrated within the tool's motor housing. This allows for precise control over the amount of torque being applied to a fastener. This is super important, because over-tightening can strip threads, and under-tightening can lead to things falling apart. So, the torque sensor ensures everything is just right Goldilocks would be proud!

Steering Systems

2. EPS and Torque Sensors

Let's dive deeper into steering systems. As mentioned earlier, Electric Power Steering (EPS) systems are a prime location for torque sensors. These sensors are vital for providing the right amount of steering assistance. Without them, steering would feel either overly sensitive or frustratingly stiff.

The sensor typically sits on the steering shaft, detecting the rotational force you're applying. This data is then sent to the EPS control module, which adjusts the amount of power assistance accordingly. It's a closed-loop system where your input is constantly monitored and adjusted for optimal steering feel. It is all about the feedback loop to prevent oversteering.

Think of it like this: imagine trying to parallel park without EPS — a real arm workout, right? Now, imagine EPS without a torque sensor — it would be like the power assist is on all the time, making the steering feel twitchy and unnatural, especially at high speeds. It is about the nuances and adjustments.

So, the torque sensor is the unsung hero of your steering system, ensuring a smooth and controlled driving experience. Its the reason you can effortlessly navigate tight corners and cruise down the highway with confidence. Next time you're driving, give a little mental nod to that little sensor working hard for you!

What Is Torque Sensor? How Does It Work? CALT Sensor

E-bikes

3. Torque Sensors and Electric Bikes

E-bikes have revolutionized the way many people commute and enjoy cycling. At the heart of this revolution is the torque sensor, which plays a crucial role in delivering a natural and intuitive riding experience. Unlike cadence sensors, which simply detect pedal rotation, torque sensors measure the actual force you're applying to the pedals.

This crucial difference allows the e-bike's motor to respond proportionally to your effort. In other words, the harder you pedal, the more assistance you receive. It feels like you have super-human legs, effortlessly conquering hills and headwinds. Plus, this provides a more natural feel.

The placement of the torque sensor on an e-bike can vary, but it's often found in the bottom bracket or sometimes in the rear hub. Bottom bracket placement offers a more direct measurement of your pedaling force, while hub-based sensors are generally easier to integrate into existing bike designs. Each placement offers its own unique engineering challenges and benefits.

So, the torque sensor in your e-bike is what makes the ride feel so seamless and responsive. It transforms your effort into extra power, making cycling more accessible and enjoyable for everyone. Time to say goodbye to those exhausting uphill battles!

Power Tools

4. Ensuring Accuracy

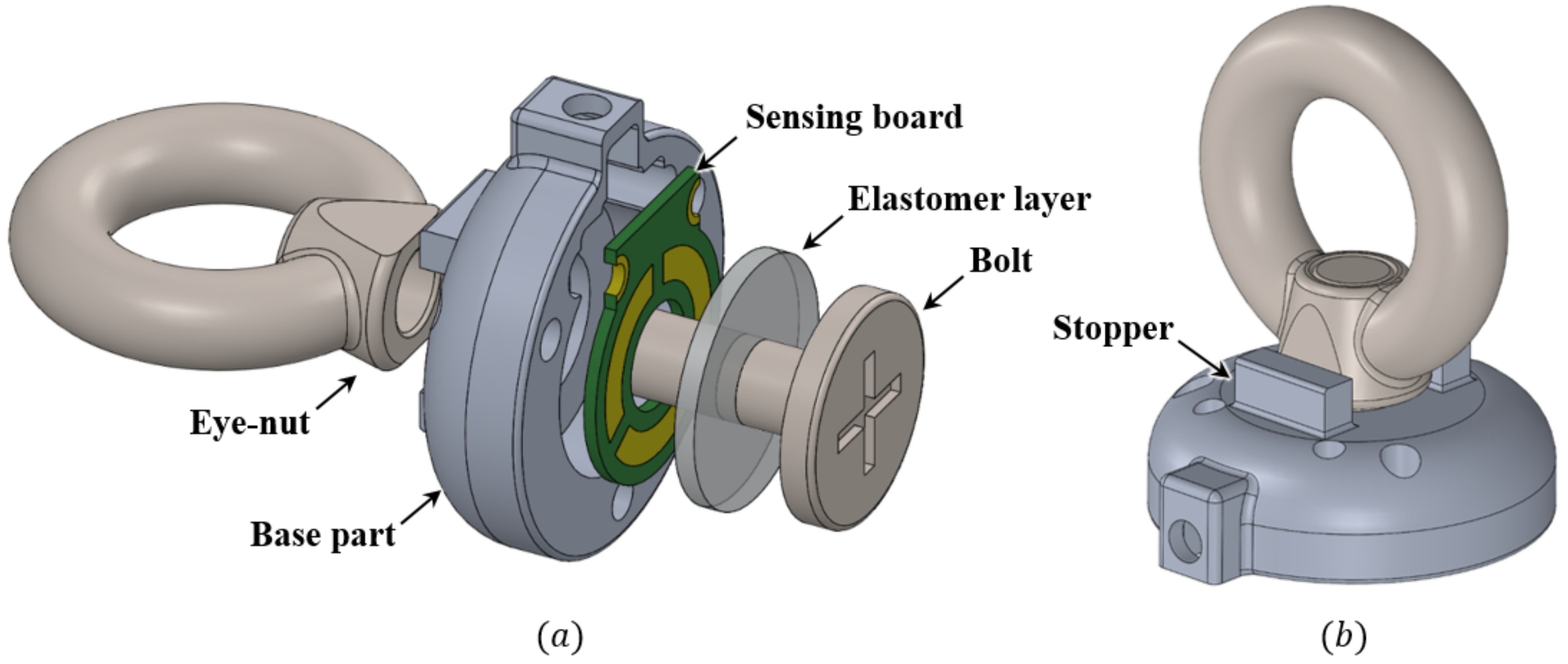

Torque sensors aren't just for vehicles and e-bikes; they're also essential components in many power tools. In applications where precision is paramount, such as assembling electronics or working on delicate machinery, torque sensors provide the accuracy needed to prevent damage and ensure proper assembly.

In electric screwdrivers, impact wrenches, and other torque-controlled tools, the sensor is typically integrated directly into the motor assembly. It monitors the amount of torque being applied to the fastener in real-time and can automatically stop the tool when the desired torque is reached.

This prevents over-tightening, which can strip threads or damage components, and under-tightening, which can lead to loose connections and potential failures. The torque sensor helps maintain consistency and reliability in manufacturing and repair processes. It helps to improve quality control.

These smart tools allow you to dial in the exact torque setting you need, ensuring that every fastener is tightened to the proper specification. No more guessing, no more stripped screws, and no more worries about things falling apart. Just perfect, consistent results every time.

Troubleshooting and Maintenance

5. Sensor Issues

Like any electronic component, torque sensors can sometimes experience issues that affect their performance. Recognizing the symptoms of a faulty torque sensor is crucial for maintaining the proper operation of your vehicle, e-bike, or power tool.

In vehicles, a failing torque sensor in the EPS system can manifest as inconsistent steering assist, making the steering feel either too light or too heavy. You might also notice that the steering wheel doesn't return to center properly after turning. In e-bikes, a faulty torque sensor can lead to erratic motor behavior, with the motor surging or cutting out unexpectedly. As for power tools, a torque sensor issue may mean the tool cant achieve the desired tightness.

Diagnosing a torque sensor issue often requires specialized equipment, such as a diagnostic scan tool or a multimeter. If you suspect a problem with your torque sensor, it's best to consult a qualified technician. Replacing a torque sensor typically involves removing and reinstalling the affected component and may require recalibrating the system. Don't just try to DIY everything!

Regular maintenance, such as keeping connections clean and free from corrosion, can help prevent premature failure of torque sensors. Check the manufacturer's recommendations for specific maintenance procedures. It is the simplest thing to do in order to maintain it.