Nice Tips About What Is PCB Relay

What Exactly IS a PCB Relay? Let's Demystify It!

1. Understanding the Basics of PCB Relays

Alright, so you've stumbled upon "PCB relay" and are probably wondering what in the world it is. No worries, it's not as complicated as it sounds! Think of it like a light switch, but instead of flipping it with your finger, you're controlling it with electricity. A PCB relay is essentially an electrically operated switch that's mounted directly onto a Printed Circuit Board (PCB). It allows a low-power circuit to control a high-power circuit. Pretty neat, right?

Imagine you're building a fancy coffee maker. You need a low-voltage microcontroller to turn on the high-voltage heating element. You wouldn't want to directly connect those, would you? That's where our trusty PCB relay comes in. It acts as the middleman, isolating the sensitive control circuit from the potentially dangerous power circuit. It's like having a highly skilled bodyguard for your electronics!

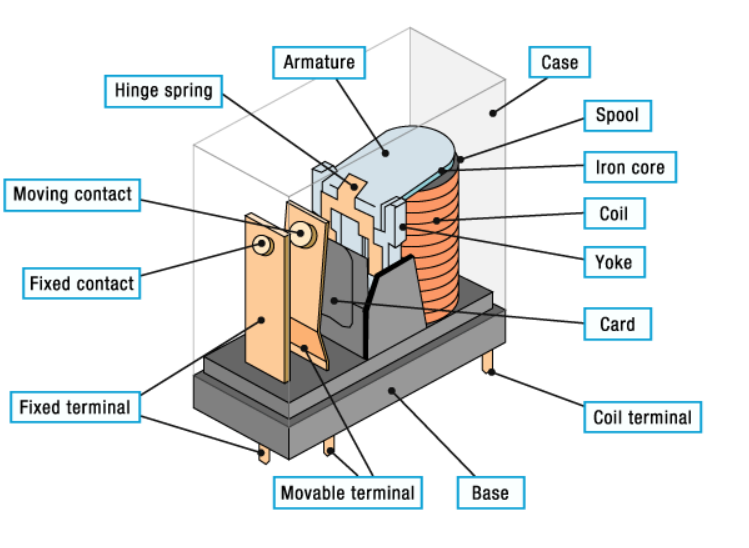

So, to break it down further, a PCB relay typically consists of a coil, an armature, and a set of contacts. When you apply a voltage to the coil, it creates a magnetic field. This magnetic field pulls the armature, which in turn moves the contacts, either opening or closing the circuit. Think of it as a tiny electric muscle flexing and switching things on and off. It's all about leveraging magnetism to make things happen.

The cool thing about PCB relays is their versatility. They come in all sorts of shapes and sizes, designed for different voltages, currents, and applications. Whether you're building a simple home automation system or a complex industrial control panel, there's likely a PCB relay perfectly suited for the job. It's like finding the right tool for the task, ensuring your project runs smoothly and safely.

PCB Relay The Ultimate Guide PCBA Manufacturers

Why Use a PCB Relay? The Advantages Are Clear!

2. Exploring the Benefits of PCB Relays

Okay, now that we know what a PCB relay is, let's talk about why you'd want to use one. There are several compelling reasons, and they all boil down to safety, efficiency, and design flexibility. Let's delve into why these little devices are so vital in a multitude of electronic designs.

First and foremost, isolation. We briefly touched on it earlier, but it's worth emphasizing. PCB relays provide excellent electrical isolation between the control circuit and the load circuit. This prevents damaging voltage spikes or surges from frying your delicate microcontroller or other sensitive components. It's like having an insurance policy for your circuits, protecting them from unforeseen electrical disasters. Plus, it's really important from a safety perspective to keep humans safe from high-voltage stuff!

Secondly, PCB relays are incredibly versatile. They can switch both AC and DC loads, and they come in a wide range of voltage and current ratings. This means you can use them in various applications, from controlling small lights and motors to switching high-power appliances. It's like having a universal remote for your electrical circuits, allowing you to control almost anything with a small signal.

Finally, PCB relays are generally reliable and long-lasting. They can withstand millions of switching cycles, making them a robust choice for demanding applications. They're also relatively easy to integrate into PCB designs, with standard pinouts and footprints. Think of them as the dependable workhorses of the electronics world, consistently delivering reliable performance for years to come. It's all about peace of mind when your product must handle a heavy workload.

Types of PCB Relays

3. Differentiating Common PCB Relay Types

Just like there are many types of cars, there are different types of PCB relays, each designed for specific purposes. Knowing the main types can help you choose the right one for your project. Let's take a quick look at some of the most common types you'll encounter.

First up, we have Electromechanical Relays (EMRs). These are the classic relays we described earlier, with a coil, armature, and contacts. They're relatively inexpensive and widely available, making them a popular choice for many applications. However, they can be a bit bulky and slower than other types. They also produce a small "click" when switching, which can be annoying in some situations (or satisfying, depending on your preferences!).

Next, there are Solid State Relays (SSRs). These relays use semiconductor devices like transistors or thyristors to switch the load. They're faster, smaller, and more reliable than EMRs, and they don't produce any clicking noise. However, they can be more expensive and may have higher on-state resistance, which can lead to heat dissipation. SSRs shine in applications where speed and silent operation are paramount.

Then we have Reed Relays. These are small, sealed relays with contacts made of reed switches. They're known for their fast switching speed and low contact resistance. They're often used in high-frequency applications or where very clean switching is required. Think of them as the sprinters of the relay world, offering lightning-fast performance.

And let's not forget Latching Relays. These relays require only a brief pulse of power to switch states and remain in that state even after the power is removed. They're great for applications where you want to minimize power consumption or maintain a state even during power outages. They're like the energy-saving experts of the relay family, always looking for ways to conserve power.

What Is PCB Relay? How Does Relay Work? NextPCB

Selecting the Right PCB Relay

4. Factors to Consider When Choosing a PCB Relay

Choosing the right PCB relay can feel like navigating a maze, but it doesn't have to be! Several key factors will guide you to the perfect choice. Consider these aspects to streamline your selection process.

First, you need to determine the voltage and current requirements of your load circuit. The relay must be able to handle the maximum voltage and current that will be flowing through it. Exceeding these ratings can damage the relay or even cause a fire, so it's always better to err on the side of caution. Make sure to check the datasheet carefully!

Second, consider the coil voltage and current required to activate the relay. This voltage must be compatible with the output of your control circuit. For example, if your microcontroller outputs 5V, you'll need a relay with a 5V coil. Matching these values ensures the relay will activate reliably.

Third, think about the switching speed required for your application. If you need to switch the load very quickly, you'll want to choose a fast relay like an SSR or reed relay. If speed isn't critical, an EMR may be sufficient. Evaluate whether your application benefits from speed or prioritizes other features.

Finally, consider the environmental conditions in which the relay will be operating. If the relay will be exposed to moisture, dust, or extreme temperatures, you'll need to choose a relay that is properly sealed or rated for those conditions. Protecting the relay ensures reliable operation even in harsh environments. It's a lot like picking the right jacket for the weather, and choosing the right PCB relay for the environment can save headaches down the line.

Troubleshooting Common PCB Relay Issues

5. Addressing Problems and Ensuring Reliable Operation

Even the most dependable components can sometimes run into snags. Here's a quick guide to help you troubleshoot some common issues you might encounter with PCB relays. Knowing these issues can help maintain optimal performance and potentially extend the lifespan of the relay.

One common problem is the relay failing to activate. This could be due to a faulty coil, insufficient voltage applied to the coil, or a broken connection in the control circuit. Start by checking the voltage at the coil terminals with a multimeter. If there's no voltage, trace the circuit back to the source and look for any breaks or shorts. If there is voltage, the coil itself might be damaged, requiring a replacement. Think of it as checking the engine of a car if it won't start methodical troubleshooting is key!

Another issue is the relay activating but not switching the load. This could be due to dirty or damaged contacts, a broken connection in the load circuit, or a blown fuse. Use a multimeter to check the continuity of the contacts when the relay is activated. If there's no continuity, the contacts are likely dirty or damaged. Try cleaning them with a contact cleaner or replacing the relay. Also, verify the load circuit to ensure it is complete and the power is delivered properly. Its possible the relay itself is fine, and there's another problem farther down the line.

Sometimes, relays can chatte, meaning they rapidly switch on and off. This can be caused by insufficient coil voltage, excessive vibration, or a faulty relay. Make sure the coil voltage is within the specified range. If vibration is the issue, try isolating the relay from the source of vibration with rubber mounts. If those don't work, the relay might be defective and need to be replaced. Chattering may seem minor, but it can ultimately cause damage.

Finally, keep an eye out for overheating. Excessive current through the contacts can cause the relay to overheat and eventually fail. Make sure you're not exceeding the relay's current rating and that the relay is properly ventilated. A heatsink can also help dissipate heat in high-current applications. Overheating often leads to premature failure and can be easily avoided with proper planning. Treat your electronics like a well-cared-for car to prevent breakdowns!

Frequently Asked Questions (FAQs) About PCB Relays

6. Answering Common Queries About PCB Relays

Let's tackle some of the burning questions people often have about PCB relays. Hopefully, this clarifies anything still a bit murky!

7. What's the difference between a relay and a contactor?

While both are electrically operated switches, relays are generally smaller and used for lower-power applications, typically on PCBs. Contactors are larger and designed for switching much higher currents, often found in industrial equipment and power distribution systems. Think of relays as the light switches in your home and contactors as the circuit breakers that power your entire house. Relays are more precise for lower power, while contactors provide the muscle for high current loads.

8. Can I replace a PCB relay with a different type of relay?

Yes, but you need to carefully consider the voltage, current, and switching speed requirements of your application. Make sure the replacement relay has compatible specifications and the same pinout as the original relay. Also, consider any other critical factors like physical size and operating environment. In short, it's doable, but research is key to ensure a successful swap!

9. How long does a PCB relay typically last?

The lifespan of a PCB relay depends on several factors, including the type of relay, the load current, the switching frequency, and the environmental conditions. Generally, electromechanical relays are rated for millions of switching cycles, while solid-state relays can last even longer. Refer to the manufacturer's datasheet for specific lifetime expectations. With proper care and usage, these components can remain operational for quite a while!