Best Info About What Are The Advantages Of A 3-phase AC Circuit

How To Connect 3 Phase Power Supply At Riley Carmen Blog

Unlocking the Power of Three

1. The Basics of 3-Phase Power

Ever wondered why large industrial sites and even your friendly neighborhood power grid rely so heavily on something called 3-phase AC? Well, its not just some fancy engineering jargon. It's actually a pretty ingenious way to deliver electrical power more efficiently and reliably. Think of it like this: instead of having one delivery truck (single-phase), you have three slightly out-of-sync trucks (three-phase) delivering goods to the same place. This coordinated effort allows for a smoother, more consistent flow of electricity, in this case!

At its heart, a 3-phase AC circuit uses three alternating currents that are offset from each other by 120 electrical degrees. This staggered delivery is the key to its many advantages. It's like having three people pushing a merry-go-round, each giving it a little nudge at slightly different times. The result? A smoother, more consistent spin, which translates to a more stable power supply.

So, what makes this "staggered delivery" so great? Prepare to have your mind mildly blown by the advantages a 3-phase system offers over its single-phase counterpart. We'll dive into those benefits shortly, breaking them down into easy-to-digest pieces, because let's face it, electrical engineering can sound like a foreign language sometimes.

Ultimately, understanding 3-phase AC is about appreciating how clever engineers have devised ways to move energy from point A to point B with maximum efficiency and reliability. And while the math behind it can get complicated, the basic concepts are surprisingly intuitive. Think of it as a team effort where each phase plays its part to deliver a superior power performance.

More Power, Less Fuss

2. Delivering the Goods with Less Effort

One of the biggest advantages of a 3-phase system is its superior efficiency. For the same amount of power delivered, a 3-phase system requires smaller conductors (wires) compared to a single-phase system. Imagine trying to carry all your groceries in one overloaded bag versus distributing them evenly across three bags. The three-bag approach (3-phase) is much easier on the "conductors" (your arms) and prevents potential "overload" (damaged wires or even fires!).

This reduction in conductor size translates directly into cost savings, especially over long distances. Think about the massive power lines that crisscross the country. If those lines had to be significantly thicker to carry the same power using a single-phase system, the cost of materials and infrastructure would be astronomical. It's like choosing between building a small bridge and a massive suspension bridge — the difference in cost is, well, substantial!

Furthermore, 3-phase motors and generators tend to be more efficient than their single-phase counterparts. This is because the rotating magnetic field in a 3-phase motor is more uniform and consistent. This smoother operation reduces energy losses due to vibration and heat. Think of it as a well-oiled machine running smoothly versus a clunky, inefficient machine that wastes energy with every movement.

In essence, 3-phase systems deliver more power with less effort, reducing both capital costs and operational expenses. And in a world increasingly focused on energy efficiency, that's a pretty big deal. So, the next time you see those high-voltage power lines, remember that they're not just there for show; they're a testament to the efficiency of 3-phase AC power delivery.

Smooth Operator

3. Say Goodbye to Power Fluctuations

Another key advantage of 3-phase AC is the constant power delivery it provides. Unlike single-phase power, which pulsates and varies over time, 3-phase power delivers a more consistent and even flow of energy. Remember those delivery trucks? Because they're staggered, there's always one "truck" delivering power, ensuring a more continuous stream of energy.

This constant power delivery is particularly crucial for sensitive equipment and heavy machinery. Imagine a precision milling machine relying on a pulsating power supply. The variations in power could lead to inaccuracies and damage to the workpiece. A 3-phase system, with its smoother power delivery, ensures consistent performance and reduces the risk of equipment malfunction. Its like having a steady hand versus a shaky one when performing delicate surgery.

The lack of power pulsations also translates to smoother operation for 3-phase motors. Single-phase motors often require additional components to start and run smoothly, while 3-phase motors start more easily and maintain a more constant speed. This makes them ideal for applications requiring precise control, such as conveyor belts, pumps, and fans. It is also safer to operate with precision equipment since you can ensure consistent current supply.

In practical terms, this constant power delivery means less flicker in lighting, more reliable operation of electronic devices, and greater stability for industrial processes. It's the backbone of modern industry and a key reason why 3-phase systems are the preferred choice for powering large-scale operations. Stability and consistent energy are very important in day-to-day operations.

3 Phase AC Circuit For FEE Mode) PDF Manufactured

Starting Strong

4. Getting Things Moving with Ease

3-phase motors are known for their superior starting torque compared to single-phase motors. Starting torque is the rotational force a motor can produce when it first starts up. Think of it as the initial push needed to get a heavy object moving. 3-phase motors have a natural advantage here due to their inherent design and the balanced nature of the three-phase power supply.

This high starting torque is especially important for applications requiring motors to start under heavy loads, such as pumps, compressors, and elevators. A single-phase motor might struggle to get these loads moving, requiring additional starting mechanisms and potentially causing damage to the motor over time. A 3-phase motor, on the other hand, can effortlessly handle these demanding starting conditions. It is like having a strong arm to crank up the object into movement.

The ability to start under load also contributes to the overall efficiency of 3-phase systems. By eliminating the need for auxiliary starting equipment, 3-phase motors reduce energy consumption and simplify the overall system design. This not only saves money but also improves reliability and reduces maintenance requirements. Simpler equipment makes for better and more efficient usage of electricity.

In short, the superior starting torque of 3-phase motors makes them the ideal choice for applications requiring high power and reliable starting performance. It's a key factor in their widespread use in industrial settings and a testament to the ingenuity of 3-phase power systems. No need for extra gears to get the equipment running!

Three Phase AC Generators Inst Tools

Versatility and Scalability

5. Powering Everything from Small Workshops to Giant Factories

3-phase AC systems are incredibly versatile and scalable, making them suitable for a wide range of applications, from small workshops to large industrial facilities. You can easily adapt them to different voltage and current requirements, ensuring optimal performance for various types of equipment. It's like having a power system that can grow with your needs, whether you're running a small business or a massive manufacturing plant.

This scalability is particularly important in modern industrial environments, where power demands can fluctuate significantly. A 3-phase system can be easily expanded to accommodate increased power requirements, ensuring that your operations can continue to run smoothly even as your business grows. It's a future-proof solution that can adapt to changing needs without requiring a complete overhaul of your electrical infrastructure. No need to worry about the system failing.

Furthermore, 3-phase power can be easily converted to single-phase power for powering smaller loads, such as lighting and office equipment. This flexibility allows you to optimize your power distribution system, ensuring that each load receives the appropriate voltage and current. You can manage it and monitor each phase to ensure everything is running smoothly.

In conclusion, the versatility and scalability of 3-phase AC systems make them the preferred choice for powering a wide range of applications. Whether you're running a small workshop or a giant factory, a 3-phase system can be tailored to meet your specific needs, providing reliable and efficient power delivery for years to come. It's a robust and adaptable solution that forms the backbone of modern power distribution networks.

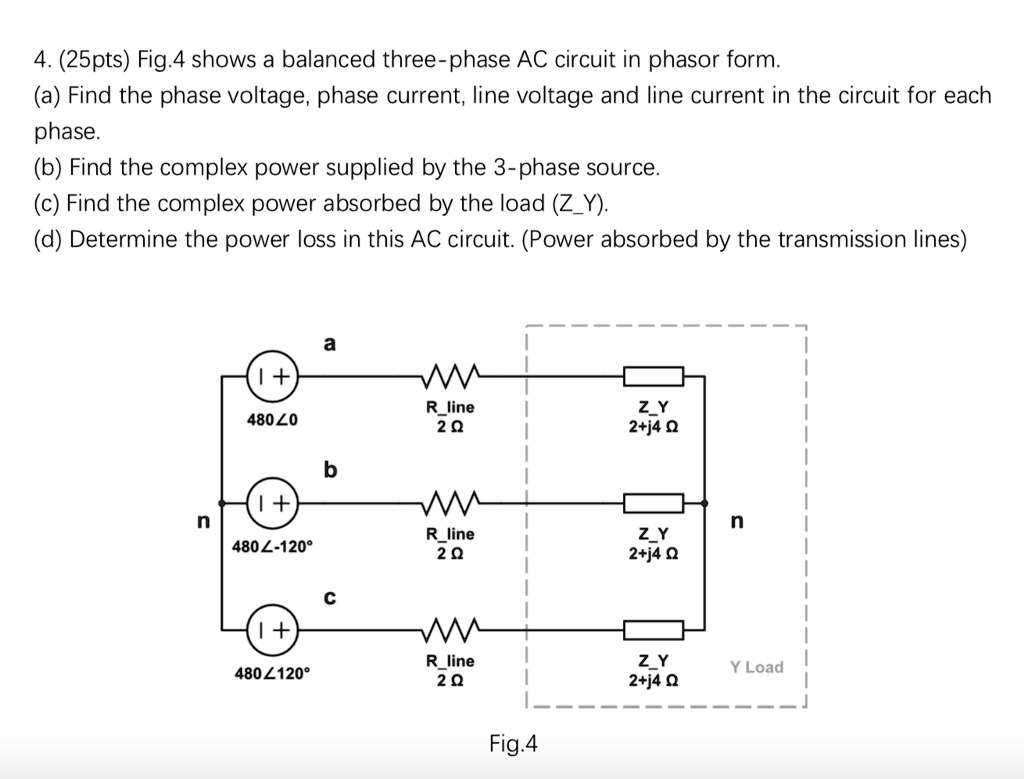

SOLVED Fig. 4 Shows A Balanced Threephase AC Circuit In Phasor Form

FAQ

6. Q

A: While 3-phase power is common in industrial settings, it's not typically used in residential homes. The standard voltage in homes is generally single-phase 120V. However, some larger homes with heavy electrical loads (like large air conditioning systems or electric vehicle chargers) might have a 3-phase connection. If you're unsure, consult a qualified electrician to evaluate your specific needs. Remember, electricity is serious stuff!

7. Q

A: Yes, you can! There are devices called rotary phase converters or static phase converters that can convert single-phase power to 3-phase power. However, these converters can be expensive and may not be suitable for all applications. The best option depends on the size and type of load you need to power. Talk to an electrical specialist before making any changes or adjustments.

8. Q

A: If one phase is lost in a 3-phase system (a condition known as "single-phasing"), it can cause significant problems, especially for motors. Motors can overheat and potentially burn out if they continue to run on only two phases. Protective devices, such as phase monitors, are often used to detect single-phasing and automatically shut down the equipment to prevent damage. Best to check regularly that all your phases are fully operating.