Best Info About What Is Connector Coupling

Understanding Connector Coupling

1. What Makes Connector Coupling Important?

Ever wondered what really happens when you plug two things together? It's not just a simple snap; there's some science involved, especially when we're talking about connectors. Connector coupling, in simple terms, refers to how well two connectors join together to form a reliable electrical or data connection. Think of it like a handshake. A firm, solid grip (good coupling) ensures clear communication, while a weak, flimsy one (poor coupling) leads to misunderstandings — or in the connector world, signal loss or even a complete connection failure.

Why should you care? Well, if you rely on any kind of electronic device (spoiler alert: you do), connector coupling is silently working (or not working!) behind the scenes. From your phone charging cable to the complex wiring inside your computer, the quality of the connector coupling directly impacts the performance and longevity of your gadgets. A weak coupling can lead to intermittent connection issues, frustrating data transfer speeds, and even damage to your equipment over time. It's the unsung hero (or villain) of the digital age!

The phrase "connector coupling" itself is a noun phrase. It represents the act or state of two connectors being joined. This is the core idea we're exploring, so understanding its importance is, well, crucial. We're not just talking about connectors in general; we're focusing on the quality of their connection. That quality hinges on the coupling.

So, what factors contribute to good connector coupling? We'll dive into that shortly, but keep in mind it's not as simple as just shoving two pieces together really hard! It involves precision engineering, material science, and a bit of physics thrown in for good measure. Get ready for a journey into the surprisingly fascinating world of connectors!

The Nuts and Bolts

2. Material, Design, and More

Alright, let's get down to what actually makes connector coupling effective. It's not just about brute force; it's about finesse. Several factors play a crucial role, starting with the materials used. The type of metal (or even plastic) in the connector can significantly impact its conductivity, resistance to corrosion, and overall durability. Gold plating, for instance, is often used on high-end connectors because it's an excellent conductor and resists tarnishing, ensuring a consistent connection over time. But even the base metal underneath matters; you can't just slap gold on cheap steel and expect miracles!

Design is equally vital. The shape and size of the connector pins, the tightness of the fit, and even the presence of locking mechanisms all contribute to the strength and reliability of the coupling. A poorly designed connector might be easy to plug in, but it could also be prone to accidental disconnections or wobbly connections that cause intermittent problems. Precision is key. Think of it like a perfectly fitted puzzle piece versus one that's forced into place; the former is a sign of good design, the latter... well, prepare for frustration.

Environmental factors also matter. Extreme temperatures, humidity, and even vibrations can wreak havoc on connector coupling. Connectors used in harsh environments need to be specifically designed to withstand these challenges. This might involve using special sealing materials to prevent moisture ingress or employing robust locking mechanisms to prevent accidental disconnections in vibrating environments. Think about the connectors on your car; they have to endure a lot of abuse!

Finally, manufacturing tolerances play a huge role. Even the best design can be ruined by sloppy manufacturing. If the dimensions of the connector components are not precise, the coupling will suffer. This is why quality control is so important in the connector industry. Every connector should be thoroughly tested to ensure it meets the required performance standards.

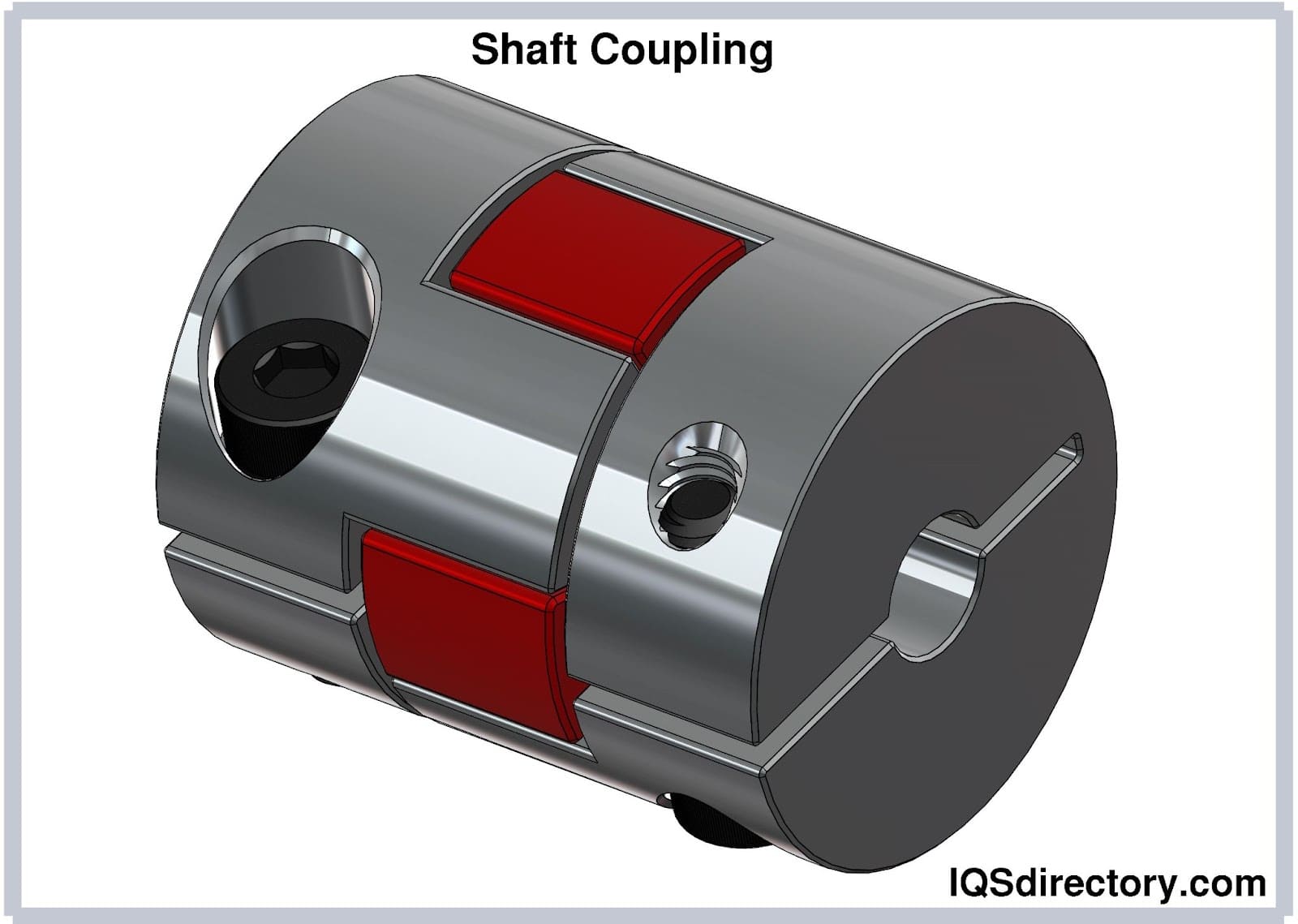

Roles And Types Of Shaft Couplings

Troubleshooting Connector Coupling Problems

3. Spotting and Solving Connection Issues

So, you suspect you've got a connector coupling issue. How do you go about diagnosing and fixing it? First, a visual inspection is your best friend. Look for signs of damage, corrosion, or loose connections. Are the connector pins bent or broken? Is there any visible rust or grime on the connector surfaces? Is the connector securely plugged in, or does it feel loose and wobbly?

Next, try cleaning the connectors. Dust, dirt, and other contaminants can interfere with the connection. Use a clean, dry cloth or a specialized connector cleaning spray to remove any debris. Avoid using abrasive cleaners, as they can damage the connector surfaces. Remember to disconnect the power before cleaning anything, just to be on the safe side!

If cleaning doesn't help, the next step is to test the connection. A multimeter can be used to check for continuity between the connector pins. If there's no continuity, that indicates a broken connection somewhere. You might also want to try swapping out the connector with a known good one to see if that resolves the issue. This is a common troubleshooting technique in electronics.

In some cases, the problem might not be with the connector itself but with the wiring connected to it. Check the wires for signs of damage, such as frayed insulation or broken strands. A loose or broken wire can also cause intermittent connection problems. If you find any damaged wires, they should be repaired or replaced by a qualified technician.

Industrial Electrical Connectors And Fittings

The Future of Connector Coupling

4. Innovations and Emerging Technologies

The world of connector coupling isn't standing still. As technology advances, connectors need to keep up. We're seeing a growing demand for smaller, faster, and more reliable connectors. This is driving innovation in materials, design, and manufacturing processes. For instance, new materials like carbon nanotubes are being explored for their superior conductivity and strength.

Wireless technology might seem to threaten the need for connectors, but it's actually creating new opportunities. Consider wireless charging; it still requires a connector at one end, and the efficiency of that connection impacts charging speed. Even as devices become more wireless, the need for robust and reliable connectors will remain. The Internet of Things (IoT) is also fueling connector innovation. With billions of devices connected to the internet, there's a huge demand for low-power, high-density connectors that can operate in challenging environments.

Another trend is the increasing use of simulation and modeling in connector design. Computer-aided engineering (CAE) tools allow engineers to simulate the performance of connectors under various conditions, optimizing their design for maximum reliability. This reduces the need for physical prototypes and accelerates the development process. Think of it as a virtual wind tunnel for connectors!

Finally, we're seeing a greater emphasis on sustainability in the connector industry. Manufacturers are looking for ways to reduce the environmental impact of their products, using more eco-friendly materials and processes. This is driven by both consumer demand and government regulations. The future of connector coupling is not just about performance; it's also about responsibility.

CNC Machine Spindle Curved Jaw Type Flexible Connector Coupling

Connector Coupling

5. Your Questions Answered

Still have questions about connector coupling? Here are some frequently asked questions to help you further understand this critical aspect of electronics:

Q: What is the difference between connector coupling and connector mating?A: Connector mating refers to the physical act of joining two connectors together. Connector coupling, on the other hand, refers to the quality and effectiveness of that connection. Mating is the action; coupling is the result.

Q: Can poor connector coupling cause damage to my devices?A: Yes, absolutely. A weak or intermittent connection can cause voltage fluctuations or signal interruptions, which can damage sensitive electronic components over time. It's like feeding your computer a diet of electricity hiccups — eventually, it's going to protest!

Q: How often should I clean my connectors?A: It depends on the environment. In dusty or dirty environments, you should clean your connectors more frequently — perhaps every few months. In cleaner environments, you might only need to clean them once or twice a year. Use your best judgment, and if you notice any signs of corrosion or contamination, clean them immediately.

Q: Are all connectors created equal?A: Nope! Just like cars, some connectors are built for performance, others for economy, and some are just plain lemons. Investing in quality connectors, especially for critical applications, can save you a lot of headaches down the road.